2014 Electrical Insulation Conference, Philadelphia, Pennsylvania

Abstract— On-line partial discharge (PD) measurement is now widely applied to motors rated 6 kV and above that are fed from the 50/60 Hz power system. However, during the past several years, many motors are being powered from inverters which facilitate variable speed motors to improve process efficiencies. One of the drives now being used is of the voltage source, pulse width modulation (VS-PWM) type. Such drives generate high voltage impulses in the kV range with risetimes in the sub-microsecond range. These high voltage spikes are a form of severe electrical interference which can make the detection of PD (with magnitudes 1000 x smaller) difficult due to the overlapping frequency content in PD and the spikes. Thus PD detection on VS-PWM has been a challenge in spite of the serious insulation aging that such drives may cause. This paper outlines the challenges in measuring the stator winding PD in motors fed by VS-PWM drives and describes a newly-developed measurement system. Initial results from a 45 MW compressor motor are presented.

Keywords – Partial discharge, variable speed drives, stator windings.

I. INTRODUCTION

Due to ever decreasing cost, variable speed drives are becoming more popular for energy conservation and the reduction in inrush currents. The type of drive that is becoming more popular today employs a voltage-source, pulse width modulated (VS-PWM) inverter, since it tends to be more economical than other possible topologies. Unfortunately, such inverters produce 1000 or more short-risetime voltage impulses per second of both polarities. It was first noted in the early 1990s that even in low-voltage random-wound stators fed by such drives, the stator winding insulation tended to fail prematurely, often after only a few months of operation [1]. The root cause was partial discharge (PD) usually occurring between the coil turns in small voids [2, 3, 4]. This led to the IEC requirement that such random-wound stators be PD-free up to the maximum impulse voltage to which a specific motor may be subject [2]. As a consequence, methods were developed to detect PD in the presence of 100 ns risetime voltage impulses [5, 6]. Commercial systems tend to use UHF antenna (either patch antenna or horns) or UHF directional electromagnetic couplers. Since IEC 60034-18-41 was first published in 2006 [2], most manufacturers of low voltage inverter duty motors perform this factory (off-line) PD test. Although there seems to be little requirement for on-line testing of random-wound motors fed by VS-PWM drives, the methods developed for off-line testing can usually be used with on-line testing.

In the past decade, medium and high voltage motors (2.4 kV to 13.8 kV) fed by VS-PWM drives have become more common. Currently, motors rated up to 80 MW are being designed. The higher the rated voltage, the more levels are usually used in the drive. From their first use in military applications, the motors fed by VS-PWM drives have often seen stator insulation premature aging. For medium and high voltage motors, the stators are usually form-wound. As discussed below, the voltage impulses from the drive can lead to rapid stator insulation system aging [7 – 10]. In most cases, as the aging progresses the PD activity increases. Thus, just as for conventional power frequency motors, there is a desire for on-line PD detection of these medium and high voltage motors. Unfortunately, conventional electrical PD detectors tend to be overwhelmed by the 1000-3000 V impulses created by multi-stage VS-PWM drives. The risetime of the voltage impulses from the multi-stage VS-PWM drives tend to be 500 ns or longer. This paper describes the technical issues in on-line PD detection on motors fed by VS-PWM drives and gives an example of one system that detects the PD successfully.

II. EFFECT OF INVERTER PULSES ON MEDIUM VOLTAGE MACHINES

Experience over the past decade indicates that the voltage impulses from the VS-PWM inverters can age each component of the stator insulation system differently. For all components, PD is a cause or a symptom of this aging.

A. Turn Insulation Deterioration

As found with low voltage random-wound stators [1, 2, 10, short-risetime voltage impulses will apply a disproportionately high voltage across the turns in the coils connected to the line end of the stator winding. A high interturn voltage can give rise to a partial discharge if there is an air pocket in the vicinity of the turns. Although such PD may occur in form-wound stators, it is not as dangerous as in random-wound machines which have purely organic insulation. This is because form-wound stators for VS-PWM applications are likely to use mica paper turn insulation, which is very resistant to PD.

B. Ground and Phase Insulation

In form-wound windings, inverters tend to cause a higher peak phase-to-ground electrical stress than normal 50/60 Hz voltage [7, 9]. This is a result of the short-risetime switching voltage and the associated transmission line reflection effects which may lead to voltage doubling, which in turn, results in the peak-voltage to rms-voltage ratio being higher than the 1.4 ratio that is present with sinusoidal voltage. The actual peak voltage depends on the number of levels in the VS-PWM drive (more levels yield a lower peak impulse voltage). The higher peak voltage will increase the number and magnitude of groundwall insulation partial discharge and thus accelerate aging. The number of PD pulses may also be higher than for a conventional 50/60 Hz motor since the switching frequency is 1000 Hz or more and each resulting impulse may create PD in a void.

C. Stress Relief Coatings

Since inverters generate high-frequency voltages, the capacitive currents through the ground insulation are relatively high compared to power frequency. OEMs have found it prudent to employ semiconducting and silicon carbide coatings on VS-PWM motors rated as low as 3.3 kV to control the stress distribution in the endwindings, and thus avoid PD at the slot exits. The high-frequency capacitive currents will result in high local I2R losses in the coatings compared to power frequency windings [7 – 9]. The result is that the stress control layers in VS-PWM inverter fed motors are likely to deteriorate much faster than the layers in 50/60 Hz windings due to the resulting high temperature. As the stress relief coatings deteriorate, they will create PD activity.

III. DIFFICULTIES IN MEASURING ON-LINE PD IN DRIVE SYSTEMS

Off-line and on-line PD testing of conventional motors has been performed for many decades using a range of technologies. The PD test methods are documented in IEEE 1434, IEC 60034-27 and IEC 60034-27-2. With minor modifications, these test methods can be used for variable speed motor stators using cyclo-convertors, load commutated inverters (LCI) and current source PWM inverters. Conventional PD detectors can be used since these drives do not produce short-risetime voltage impulses of any significance. LCI drives do produce voltage impulses, but they use GTO or thyristor switching devices that have risetimes longer than 1 μs, which can be readily filtered out by PD detectors operating in the VHF (30-300 MHz) range.

However, the VS-PWM type of drive produces significant short-risetime voltage impulses. Such drives use IGBT (or similar) switching transistors, which switch DC voltages of 1000 – 1500 V. With worst case transmission line voltage reflections of 2 times, impulse voltages may be up to 3000 V. Due to the several levels of medium and high voltage inverters, the risetime of these impulses has been measured to be about 500 ns or more. In contrast, 3-level inverters produce risetimes as short as 100 ns [2, 3]. Using a Fourier transform, a 500 ns risetime impulse will produce frequencies up to about 600 kHz. Future VS-PWM drives are likely to have shorter switching times and higher switching voltages, making the situation worse.

One reason that PD measurement is difficult with VS-PWM drives is that the frequency content of the impulse voltages (which are about 1,000 times or 60 dB higher than PD pulses) significantly overlaps the frequency content of the PD. In conventional PD detection, the mV PD pulses are most commonly separated from the high voltage 50/60 Hz using a single-pole high-pass filter. With a PD detector operating in the VHF range, the high voltage 50/60 Hz is reduced to <10 mV, while the magnitude of the PD (which in air at 100 kPa has a risetime of about 3 ns) is largely unaffected. This makes it easy to extract the PD from the residual power frequency voltage. In contrast, a 500 ns risetime, 3000 V impulse may be reduced to only about 10 volts by a single pole high pass filter with a lower cut-off frequency of 40 MHz. Of course, PD detectors operating in the HF (3-30 MHz) and LF (<3 MHz) range will have even higher residuals from the voltage impulses. Clearly, additional electronic or passive filters or other means are needed to further suppress the impulse voltage another 60 dB or so in order to reduce the residual to less than the typical PD levels (using a VHF measurement method, significant PD has a magnitude of several hundred mV [10]).

For low voltage motors where the impulse risetimes are shorter and the 0-to-peak voltage is lower than for medium voltage motors, filtering alone tends to be unsuccessful in reducing the magnitude of the impulse to the required level due to the cross-coupling that effectively limits the total attenuation in real filters. Therefore, alternative methods were developed for low voltage motors based on UHF (300 – 3000 MHz) sensors. IEC 61934 reviews the methods for this application [9]. One approach is to use a directional electromagnetic coupler [5]. To date such detectors are limited to 0-to-peak total voltages of 5 kV or less. Alternatively, microwave “horn” antennae mounted close to the stator within the motor enclosure, or patch antennae mounted on the motor power supply leads, have been successfully used [6]. As with the directional electromagnetic coupler approach, the patch antenna is best for lower voltage motors, since the antenna can stimulate its own PD as it must be attached to the unshielded part of the motor power cable in the motor terminal box. The horn antenna needs “line of sight” to the PD locations without metallic barriers between it and the PD site, making it impractical for complete motors (as opposed to stators alone). Thus, the methods that have proved successful for low voltage random-wound motors may not be effective for medium and high voltage motors.

Another practical issue with PD detection in medium and high voltage VS-PWM motors is providing a voltage proportional to the fundamental frequency coming from the inverter, since it is traditional to display PD with respect to the AC sinewave. For conventional motors, the power frequency sinewave can be extracted from the PD coupler, and phase corrected for the 90 degree phase shift. Experience has shown that it is difficult to reliably synchronize to the fundamental voltage with the high magnitude voltage impulses superimposed on the fundamental AC voltage. An extremely narrow band filter would not work since the frequency of the fundamental voltage varies over a wide range (for example 10- 60 Hz).

IV. DEVELOPMENT OF AN ON-LINE PD SYSTEM FOR MEDIUM AND HIGH VOLTAGE INVERTER DRIVES

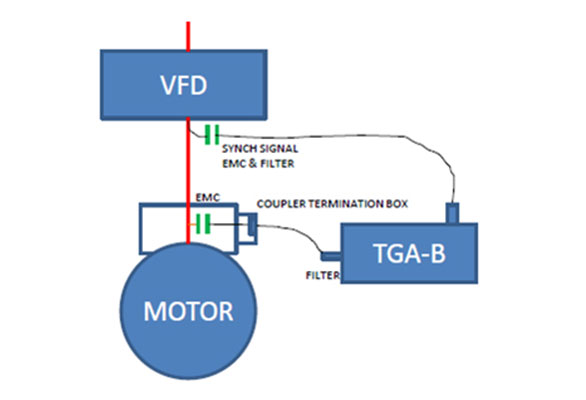

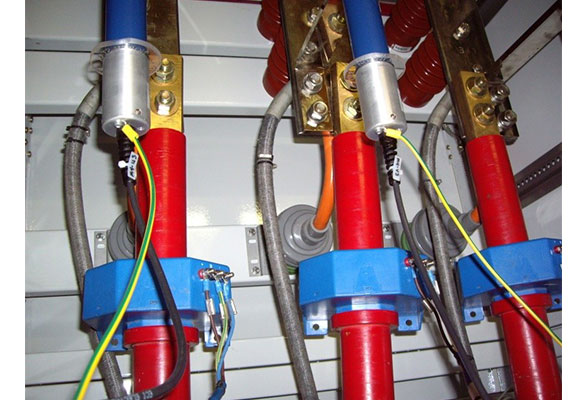

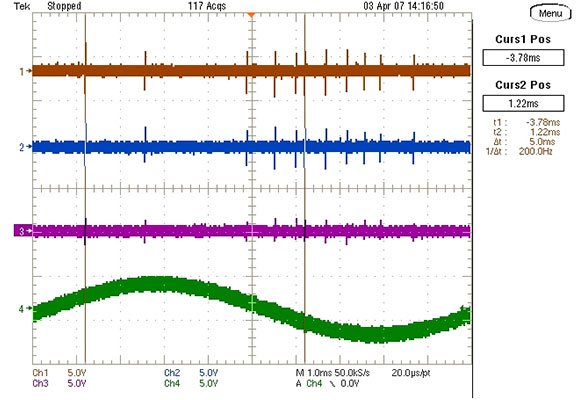

Figure 1 shows the block diagram of the prototype PD detection system intended for VS-PWM drive motors. To overcome the problem of separating the PD from the residual of the voltage impulses, the system was based on a conventional VHF on-line PD detector rather than on the UHF system developed for low voltage stators. This was possible with the use of high voltage PD sensors. The 80 pF, 16 kV capacitors use a mica splitting dielectric which yield impulse flashover voltages >100 kV and meet all the requirements of IEC 60034-27-2 and IEEE 1434 for rotating machine on-line PD sensors (Figure 2). As illustrated in Figure 3, the output of these PD sensors had residual voltage spikes from the inverter of over 3000 mV. To further reduce the magnitude of the spikes, a multi-pole high-pass filter with a 10 MHz lower cut-off was used. This filter reduced the magnitude of the PD pulses in the VHF frequency range by about 3 db.

In several prototype installations, a reliable fundamental frequency synchronization signal could not be realized using the 80 pF PD coupling capacitors. Instead a capacitive voltage divider was optimized for the frequency range 150 Hz and below. The optimum placement of the voltage divider was at the inverter output, before voltage doubling and additional ringing of the impulses occurred due to impedance mismatches (Figure 1). However, sometimes the divider did work satisfactorily when installed at the motor terminals.

Fig. 1 Schematic of PD measuring system applied to high voltage VS-PWM drives.

Fig. 2 Installation of the 80 pF capacitive sensors on the motor terminals.

Fig. 3 Oscilloscope traces of the output of the PD sensors measured across a 50 ohm resistor. The top 3 traces are the PD and noise from phases A, B, and C respectively (5 V per division). The bottom trace is the AC voltage measured on phase A (5 V per division) from a capacitive voltage divider at the drive output. The horizontal scale is 1 ms per division.

V. CASE STUDY

A prototype installation was done on several 45 MW, 7.2 kV compressor motors. The waveform of the impulse voltage measured at the stator using a high voltage divider is shown above in Figure 3 (lower trace). Figure 3 also shows the signal from three PD sensors.

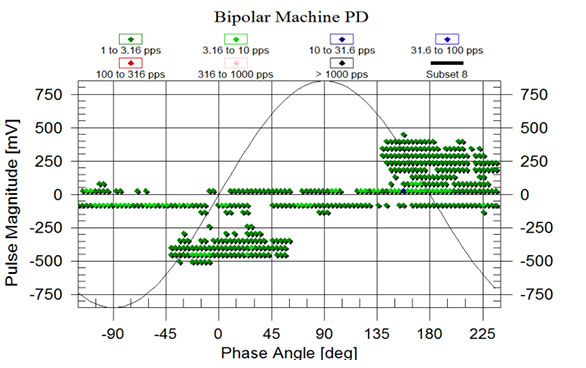

Figure 4 illustrates the phase-resolved PD signal measured by the modified VHF detector on the motor during operation. The PD pattern is typical of power frequency PD with the exception that the PD signals are phase shifted to the left. The reason for the unusual phase position of the PD clumps is not clear, but it may be due to the fact that PD is more likely to occur when there are fewer voltage impulses from the drive (i.e. near the fundamental voltage zero crossings), since PD tends to be suppressed at high repetition rates (near the fundamental voltage peaks) due to space charge [12].

Experience with VHF PD measuring systems on conventional 7.2 kV stators indicates that if the peak PD exceeds about 300 mV, significant PD is occurring [10]. Thus this stator winding appears to have significant PD activity. Regrettably, a visual examination to confirm the presence of PD has not yet been possible.

Fig. 4 AC phase resolved PD pattern from the modified VHF detector. The color displays the PD pulse repetition rate.

VI. CONCLUSION

1. Although on-line motor PD measurement from most types of medium voltage and high voltage drives is straight-forward, the newer VS-PWM drives can cause complications.

2. A conventional on-line VHF PD system has been successfully modified to measure the stator winding PD on 6 kV to 13.2 kV stators connected to VS-PWM drives. The system required extra PD pulse processing as well as a separate capacitive voltage divider to provide a fundamental frequency synchronization signal.

REFERENCES

[1] E. Persson, “Transient Effects in Applications of PWM Inverters to Induction Motors,” IEEE Trans. Industry Applications, p 1095, Sept. 1992.

[2] IEC 60034-18-41, “Rotating electrical machines – Part 18-41: Qualification and type tests for Type I electrical insulation systems used in rotating electrical machines fed from voltage converters”

[3] S. R. Campbell and G. C. Stone, “Examples of Stator Winding Partial Discharge Due To Inverter Drives,” in IEEE International Symposium on Electrical Insulation, Anaheim, April 2000, pp 231-234.

[4] W. Yin et al., “Improved Magnet Wire for Inverter-Fed Motors, in Proceedings of IEEE Electrical Insulation Conference, Chicago, September 1997, p. 379.

[5] S.R. Campbell, M. Susnik and G.C. Stone, “New Tools to Determine the Vulnerability of Stator Windings to Voltage Surges from IFDs,” Proceedings IEEE Electrical Insulation Conference, Cincinnati, Sept 1999.

[6] Cavallini, G.C. Montanari, A. Salsi, Characterization of Patch Antennae for PD Detection in Power Cables”, Proc IEEE Conference on Electrical Insulation and Dielectric Phenomena, Oct 2007, pp 179-182.

[7] IEC 60034-18-42, “Rotating electrical machines: Qualification and acceptance tests for partial discharge resistant electrical insulation systems (Type II) used in rotating electrical machines fed from voltage converters”

[8] E. Sharifi, S. Jayaram, E. Cherney, “Analysis of Thermal Stresses in Medium Voltage Motor Coils Under Repetitive Fast and High Frequency Pulses”, IEEE Trans DEI, 2010, pp 1378-1384.

[9] M. Stranges, G.C. Stone, D. Bogh, “Voltage Endurance Testing of Stator Insulation Systems for Inverter Fed Machines”, IEEE Industry Applications Magazine, Nov 2009, pp 12-18.

[10] G. C. Stone et al, “Electrical Insulation for Rotating Machines – Second Edition”, Wiley – IEEE Press, 2014

[11] IEC 61934, “Electrical insulating materials and systems – Electrical measurement of partial discharges (PD) under short rise time and repetitive voltage impulses”

[12] G.C. Stone, R. van Heeswijk, R. Bartnikas, “Investigation of the Effect of Repetitive Voltage Surges on Epoxy on Epoxy Insulation,” IEEE Trans EC, Dec 1992, pp 754-759.