Company:

West Canadian Plant

Machine Description:

13.8 kV; 90 MW; 3600 rpm, Gas Turbine Generator

Manufactured 2010

BUS EMCs (80 pF sensors)

CASE STUDY: Effective Maintenance in Generator Stator Winding

“…. The overall ‘Very High’ level causes some concern. The PD clusters indicates presence of slot area, the slot exit and interphasal discharges….”

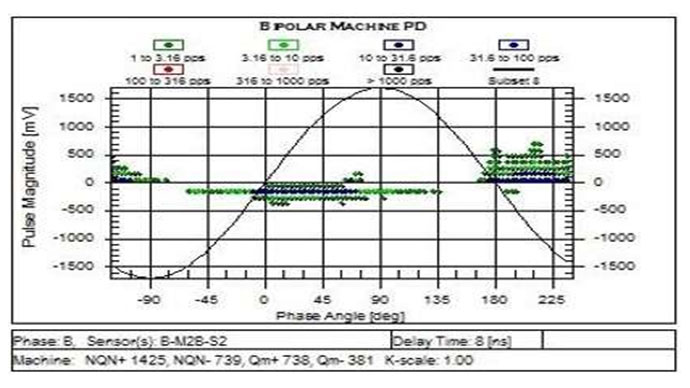

Excerpt from Partial Discharge Test Report from data taken in April 2015. Figure 1 from the report shows high PD activity.

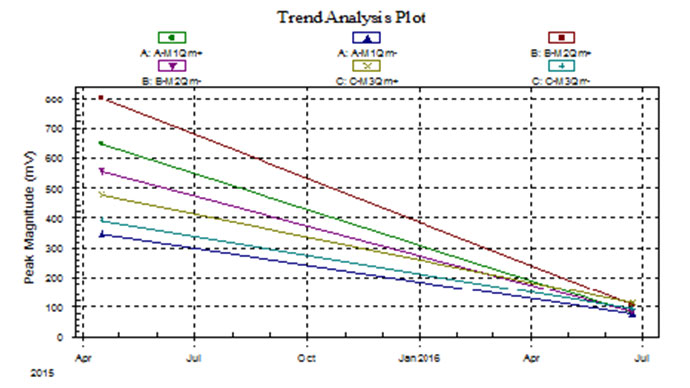

“…The PD levels in all three phases are significantly lower than in the first readings. Apparently the maintenance in 2015 (repairs to the stress relief coatings) has been successful. This is the second test done in this machine and the trend shows significant decrease in level… The LOW levels of PD compared to other air cooled windings of similar voltage class means this asset does not, as yet, have any significant problems…”

Excerpt from Partial Discharge Test Report from data taken in June 2016. Figure 2 from the report shows the trend with significant drop in PD activity as result of the maintenance work.

Figure 1 – PD data showing high surface PD

Figure 2 – Trend showing significant drop in PD activity after maintenance