Stator End-Winding Vibration as a Cause of Generator Failure

Vibration of stator bars and coils outside of the stator slot (endwinding vibration) is becoming a more common cause of motor and generator stator winding failure. If one does a regular inspection of the machine, such deterioration can be detected well before a stator winding fault by looking for signs of fretting dust, greasing and/or cracks in the varnish that often coats the endwindings. However, the preferred method of detecting stator endwinding vibration without requiring a machine outage and disassembly has been the direct measurement of vibration using fiber optic accelerometers mounted at critical locations of the endwinding. Online monitoring can also provide the benefit of correlating the vibration with operational temperature and load.

Westinghouse developed the first practical endwinding vibration monitoring system using fiber optic accelerometers in the 1980s, and many machine manufacturers now supply fiber optic accelerometers that use a variety of optical phenomena.

Iris has been supplying fiber optic accelerometers for nearly 10 years and have launched a new generation of sensors that is smaller and has proven ruggedness to work in the stator endwinding environment for many years, if not decades. The result is the patented EVAII accelerometer.

Design Improvements

This next‐generation sensor offers significant improvements over all other sensors on the market, including:

- Small sensor head (dual axis: 35x14x10 mm, single axis: 30x9x10 mm) to provide greater flexibility when choosing installation locations.

- The same fiber used to send and receive the light resulting in fewer connections offering an easier installation.

- Temperature rating of ‐50 to 230°C, which is suitable for installation in virtually all rotating machine applications.

- A vibration output that is independent of temperature.

- Exceptionally wide dynamic range.

- Immunity to magnetic fields.

- Total interchangeability in parts, providing shorter delivery time. Unlike most other sensors, the EVAII no longer has to be calibrated for a specific electro‐optical converter.

Rigorous Testing

As with all Iris sensors, the EVAII has passed rigorous long‐term accelerated aging tests in an independent test facility to ensure reliability, long life, and that the sensors themselves will never pose a risk of stator endwinding failure. These tests include:

- A series of accelerated aging tests at extreme vibration and temperature levels, intended to ensure the EVAII and feedthrough cable have a life equivalent to at least 10 years of continuous online operation at high temperature and with severe vibration.

- Partial Discharge (PD) testing which showed no observed PD activity up to 34 kV AC with a 3 pC sensitivity, indicating that the electrically non‐conducting materials of the EVAII are not sensitive to electrical fields.

- Pressure testing up to 400 psig of the penetration and fiber optic feedthrough cable bundle used to pass the signal through the gas seal in hydrogen‐cooled generators.

Scope of Offerings

The products and services Iris Power provides for endwinding vibration monitoring include:

- Solutions composed single or dual axis accelerometers together with an optional single axis accelerometer for the stator core

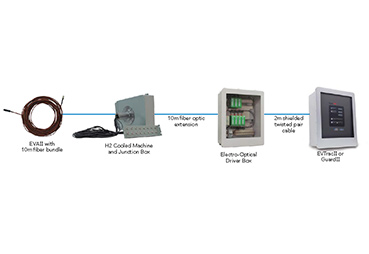

- An electro‐optical driver (EOD) box

- A junction box for air‐cooled machines or a penetration feedthrough assembly for hydrogen‐ cooled generators. The EOD is not built into the penetration, which reduces thermal and vibration stress on the EOD, and facilitates servicing without the need of a unit outage.

- Expert bump testing services together with modal analysis to determine the optimal locations for the accelerometers

- GuardII continuous monitoring systems can be used with any accelerometer that provides mV/g output. Alternatively the EOD can be connected to an existing vibration monitoring system that is compatible with its 100 mV/g output.

- Training and/or expert analysis of vibration data.

- A technical team who has been applying endwinding vibration technology for more than 30 years, and has the most extensive independent interpretation knowledge in the industry. In 2004 we were the first vendor to publish what levels of vibration were acceptable in stator endwindings.